What if a simple beverage container could withstand internal pressures exceeding 90 psi—enough to rival some pneumatic systems—while weighing a mere 13-15 grams and being produced at rates of over 2,000 units per minute? This isn’t a hypothetical aerospace component; it’s the modern aluminum can that holds your Coors Light.

A standard 12-ounce serving of Coors Light contains exactly 102 calories, with 5 grams of carbohydrates, less than 1 gram of protein, no fat, and 4.2% alcohol by volume (ABV). This positions it as one of the lighter options among mainstream American lagers, delivering Rocky Mountain refreshment without excess caloric load.

But the true engineering marvel lies in the synergy: Coors pioneered the recyclable two-piece aluminum can in 1959, revolutionizing packaging by reducing weight, improving taste preservation, and enabling sustainability. Today, that ultra-lightweight design complements the low-calorie beer inside, minimizing material use, shipping emissions, and production costs—principles mechanical engineers recognize from thin-shell structures and optimized pressure vessels.

For professionals in packaging design, consumer products, or sustainable manufacturing, Coors Light exemplifies dual optimization: precise brewing control for calorie reduction and advanced materials processing for structural efficiency. This article provides a deep dive into both, backed by historical context, material science, and manufacturing insights.

Close-up of a modern Coors Light aluminum can, highlighting its sleek, lightweight design.

Iconic silver Coors Light can emphasizing engineering and branding.

Coors Light Nutrition Facts and Calorie Breakdown

Official Nutritional Profile

According to official data from Molson Coors and consistent industry sources, a 12 fl oz (355 ml) serving of Coors Light contains:

- Calories: 102

- Carbohydrates: 5g

- Protein: <1g

- Fat: 0g

- Alcohol by Volume: 4.2%

Calorie distribution: Approximately 70% derives from alcohol (ethanol provides 7 kcal/g), with the remainder from residual carbohydrates.

Comparison with Other Beers

| Beer | Calories (12 oz) | Carbs (g) | ABV (%) |

|---|---|---|---|

| Coors Light | 102 | 5.0 | 4.2 |

| Bud Light | 110 | 6.6 | 4.2 |

| Miller Lite | 96 | 3.2 | 4.2 |

| Michelob Ultra | 95 | 2.6 | 4.2 |

| Coors Banquet (regular) | ~147 | 11.7 | 5.0 |

Coors Light strikes a balance: lower calories than Bud Light but slightly higher than ultra-low-carb options like Michelob Ultra.

Coors Light can showcasing nutritional context in modern packaging.

The History of Lightweight Engineering at Coors

Bill Coors and the Birth of the Aluminum Can

In 1959, under the leadership of Bill Coors, the Adolph Coors Company introduced the world’s first commercial two-piece recyclable aluminum beer can—a 7-ounce version for Coors Banquet.

Motivations were multifaceted:

- Eliminate metallic off-flavors from steel cans.

- Reduce weight for easier shipping and handling.

- Address environmental litter from non-recyclable steel.

- Improve seal integrity for better freshness.

Developed in collaboration with Coors Porcelain (now CoorsTek), the project overcame immense challenges, including material forming and internal lining.

Historical 1959 Coors aluminum can six-pack carrier.

Vintage photo commemorating the 1959 aluminum can introduction.

Transition to Modern 12 oz Cans

The industry shifted from impact extrusion to the more efficient draw-and-wall-ironing (DWI) process, allowing thinner walls and higher production speeds. Coors’ innovation spurred widespread adoption, transforming beverage packaging.

Structural Design of the Aluminum Beverage Can

Thin-Wall Pressure Vessel Fundamentals

The aluminum can functions as a cylindrical thin-shell pressure vessel:

- Internal carbonation pressure: 90+ psi (620 kPa).

- Hoop stress (σ_h) = Pr/t, where P = pressure, r = radius, t = wall thickness.

- Axial stress half of hoop due to end caps.

Critical features prevent buckling:

- Domed bottom for uniform stress distribution.

- Necked top for reinforcement.

Material Properties and Alloy Selection

- Body: AA3004 alloy (manganese + magnesium) for drawability and strength.

- Lid (end): AA5182 (higher magnesium) for better formability in complex shaping.

Wall thickness: Sidewalls ~0.10 mm, base thicker for support.

Current empty 12 oz can weight: 13-15 grams.

Key Design Features

- Necking and flanging for secure double-seaming with lid.

- Internal polymer coating to prevent corrosion.

Conceptual finite element analysis shows optimized geometry minimizes material while maintaining burst strength >300 psi.

Cross-section diagram illustrating structural features of an aluminum beverage can.

Detailed view of can cross-section highlighting thin walls and domed base.

Manufacturing Process: Draw and Wall Ironing (DWI)

Step-by-Step Production

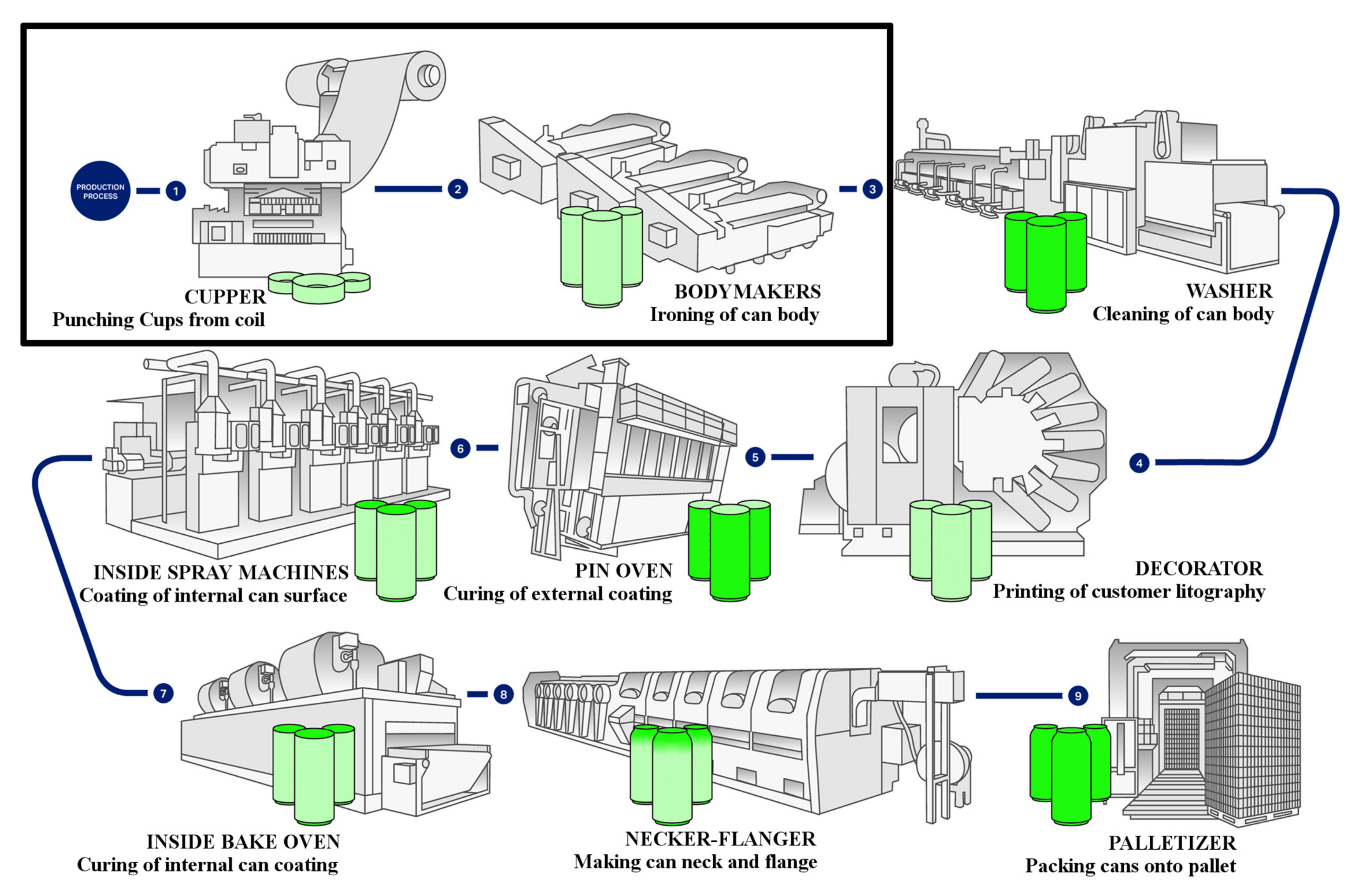

The DWI process enables ultra-thin walls:

- Coil stock to circular blanks.

- Cupping: Deep drawing into cup shape.

- Redraw and wall ironing (multiple dies progressively thin walls).

- Doming: Form reinforced bottom.

- Trimming, washing, coating, printing.

- Necking and flanging.

Production speeds reach 2,400 cans/minute.

Engineering Challenges and Solutions

- Precise lubrication to prevent tearing.

- Control of “earing” (uneven edges) via alloy composition.

- High material yield (>90%) for sustainability.

Coors Light’s silver design aids perceived cooling and branding.

Flow chart of two-piece aluminum can manufacturing process.

Wall ironing stage in DWI process.

Engineering Challenges and Solutions (continued)

Key hurdles in DWI include managing massive ironing forces (up to 10 tons per punch) while preventing defects like tearing or wrinkling. Solutions involve precise coolant-lubricant formulations and alloy tuning to control grain structure.

Coors Light cans benefit from these advancements, maintaining the iconic silver finish that enhances perceived coldness while optimizing ink adhesion for branding.

Wall ironing stage in the draw-and-wall-ironing (DWI) process for aluminum cans.

Comprehensive flow chart of two-piece aluminum beverage can manufacturing.

Detailed schematic of material flow and ironing parameters in DWI production.

Brewing Engineering Behind Coors Light Calories

The low Coors Light calories profile stems not just from packaging but from sophisticated brewing process control—a chemical engineering triumph.

Calorie Reduction Techniques in Light Beer

Light beers like Coors Light achieve lower calories through:

- Enzyme-Assisted Fermentation: Addition of amyloglucosidase breaks down complex dextrins into fermentable sugars, allowing yeast to convert more starches to alcohol and CO2, leaving fewer residual carbohydrates.

- Adjunct Usage: Corn syrup (dextrose) provides fully fermentable sugars without adding unfermentable residuals.

- Extended Cold Lagering: Prolonged maturation at near-freezing temperatures enhances clarity and removes higher-calorie compounds.

Coors emphasizes cold filtration and packaging to preserve crispness while minimizing carbs.

Process Control and Consistency

High-gravity brewing—producing a stronger wort then diluting with deoxygenated water—optimizes fermenter capacity and consistency. Mass balance and reaction kinetics ensure precise ABV (4.2%) and residual sugar levels.

This results in Coors Light’s 102 calories: balanced alcohol contribution with minimal carbs.

Overview of the Coors brewery brewing process stages.

Modern Coors brewing facility highlighting process engineering.

Comparison of Calorie Engineering Across Macros

At identical 4.2% ABV, differences arise from fermentation efficiency:

- Miller Lite: More aggressive enzyme use → 96 calories.

- Bud Light: Higher residuals → 110 calories.

- Coors Light: Optimized adjuncts and lagering → 102 calories.

Performance and Sustainability Advantages

Structural Performance

Coors Light cans routinely pass rigorous tests:

- Burst pressure: >300 psi.

- Axial load: Supports 500+ lbs before buckling.

- Drop resistance: Survives 4-ft falls onto concrete.

These metrics ensure reliability in distribution.

Environmental Impact

Lightweight design reduces shipping fuel—thousands of tons saved annually. Aluminum’s infinite recyclability means a Coors Light can today contains >70% recycled content, with recycling saving 95% energy vs. virgin production.

Molson Coors has eliminated plastic rings from Coors Light packaging, transitioning to recyclable cardboard by 2025.

Sustainable packaging initiatives for Coors Light, emphasizing recyclability.

Modern Innovations

Ongoing thinning of walls and lids, plus potential for advanced alloys, promise further weight reductions without compromising integrity.

Practical Insights for Engineers

Mechanical engineers can apply Coors Light principles broadly:

- Material Selection: Choose alloys like AA3004/5182 for formability-strength balance in thin-walled vessels.

- Process Optimization: Use DWI-inspired techniques for high-volume lightweight components.

- Prototyping Tips: Simulate internal pressures in CAD/FEA; test prototypes with hydrostatic burst rigs.

- Sustainability Integration: Prioritize recyclable materials and source reduction for lower lifecycle impact.

These lessons extend to aerospace panels, automotive bodies, or any pressure-containing structure.

Conclusion

Coors Light’s 102 calories per 12-ounce serving, delivered in a ~14-gram recyclable aluminum can, represent interconnected engineering excellence: precise brewing for lightness and advanced manufacturing for structural efficiency.

From Bill Coors’ 1959 breakthrough to today’s sustainable innovations, this iconic beer demonstrates how mechanical principles—thin-shell design, material optimization, and process control—create superior consumer products.

Engineers: Embrace seam reduction, weight minimization, and closed-loop materials in your designs. The next breakthrough might be in your hands—or your next cold Coors Light.

Frequently Asked Questions (FAQs)

How many calories are in Coors Light (12 oz)?

A standard 12-ounce serving contains exactly 102 calories, with 5g carbs and 4.2% ABV.

Why does Coors Light have fewer calories than regular beer?

Through enzyme-assisted extended fermentation and fully fermentable adjuncts, more starches convert to alcohol/CO2, leaving minimal residual sugars.

How does the aluminum can withstand carbonation pressure?

Domed base, precise wall thinning via DWI, and high-strength alloys distribute hoop/axial stresses, supporting >90 psi routinely.

Who invented the modern aluminum beer can?

Bill Coors and the Coors team in 1959, pioneering the recyclable two-piece design.

Coors Light vs. other light beers: Which is lightest?

Michelob Ultra (95 cal) edges out, followed by Miller Lite (96), Coors Light (102), Bud Light (110).

Is the Coors Light can fully recyclable?

Yes—infinitely recyclable aluminum, with high recycled content and ongoing sustainability improvements like plastic-free packaging.

Coors Light aluminum packaging highlighting infinite recyclability.