When hurricane-force winds struck a coastal infrastructure project in 2022, dozens of newly installed outdoor post lights toppled like dominoes, causing widespread blackouts, road closures, and repair costs exceeding millions. Investigations revealed a common culprit: inadequate wind load analysis during structural design, leading to insufficient foundation depth, undersized anchor bolts, and pole deflection beyond limits.

As slender cantilevered structures, outdoor post lights—widely used in parking lots, pathways, campuses, highways, and public spaces—are particularly vulnerable to overturning moments, vortex shedding, and fatigue from environmental forces. In mechanical engineering, overlooking these dynamics can result in catastrophic failures, safety hazards, and non-compliance with codes.

This comprehensive guide equips mechanical engineers with expert methodologies for robust wind load analysis and structural design of outdoor post lights. Drawing from the latest standards as of 2026—including AASHTO LTS-6 (with 2025 interim revisions) and ASCE/SEI 7-22—we cover calculations, material selection, foundation detailing, and real-world examples to ensure safe, durable installations.

With over 20 years designing structural supports for transportation and infrastructure projects, I’ve applied these principles to prevent failures in high-wind zones. This skyscraper-level resource goes beyond basic overviews, providing step-by-step equations, tables, and case studies for superior outcomes.

Examples of outdoor post light pole failures due to extreme wind events, highlighting the risks of inadequate design.

Understanding Outdoor Post Lights as Structural Elements

Types and Applications

Outdoor post lights encompass various configurations:

- Straight round or square poles (15-40 ft typical).

- Tapered poles for aesthetic and aerodynamic benefits.

- High-mast lighting (50-150 ft) for large areas like interchanges.

- With single luminaires, multiple fixtures, or decorative arms.

Applications include roadway illumination, parking facilities, pedestrian pathways, sports fields, and commercial sites. Mechanical engineers must consider loading from luminaires, banners, or attachments.

CAD renderings of tapered aluminum outdoor lighting poles, common in modern installations.

Key Structural Challenges

As cantilevers, poles experience high bending moments at the base. Dynamic effects include:

- Vortex shedding → causing oscillations.

- Galloping in ice/wind.

- Fatigue from millions of cycles in traffic-induced gusts.

Material corrosion (especially coastal) and foundation soil interaction add complexity.

Governing Standards and Codes

Primary Standards for Design

The cornerstone is AASHTO Standard Specifications for Structural Supports for Highway Signs, Luminaires, and Traffic Signals, 6th Edition (LTS-6), updated with 2025 interim revisions. These address fatigue, truck gusts, and EPA.

Complementary: ASCE/SEI 7-22 for general wind provisions, and ASCE/SEI 72-21 for steel lighting poles.

Comparison: AASHTO vs. ASCE 7

AASHTO LTS-6 prioritizes highway-specific loads (e.g., fatigue categories I-III, truck gusts). Use for roadway/proximity installations.

ASCE 7-22 provides broader wind maps and velocity pressures; suitable for non-highway (e.g., parking lots). Cross-reference for Risk Category II structures.

Other Considerations

Local amendments to IBC, special wind regions (mountains, hurricanes), and manufacturer EPA certifications.

Wind Load Fundamentals

Wind Load Theory

Velocity pressure: qz=0.00256KzKztKdKeV2q_z = 0.00256 K_z K_{zt} K_d K_e V^2 (psf) per ASCE 7-22, where V is 3-second gust speed.

Force: F=qzGCfAF = q_z G C_f A (AASHTO simplified).

Load Cases per AASHTO/ASCE

- Natural wind gusts.

- Truck-induced (highway).

- Fatigue (equivalent static).

- Ice accretion (northern climates).

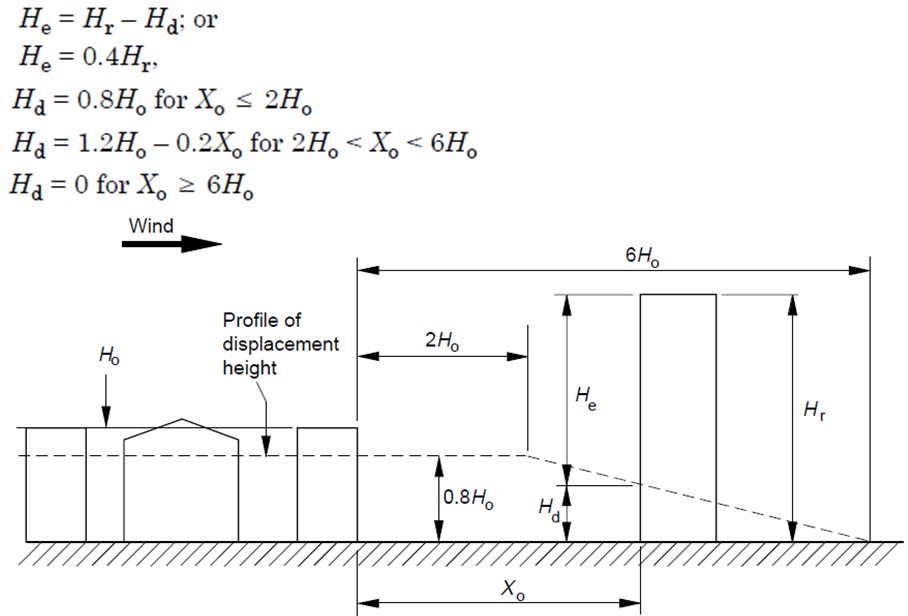

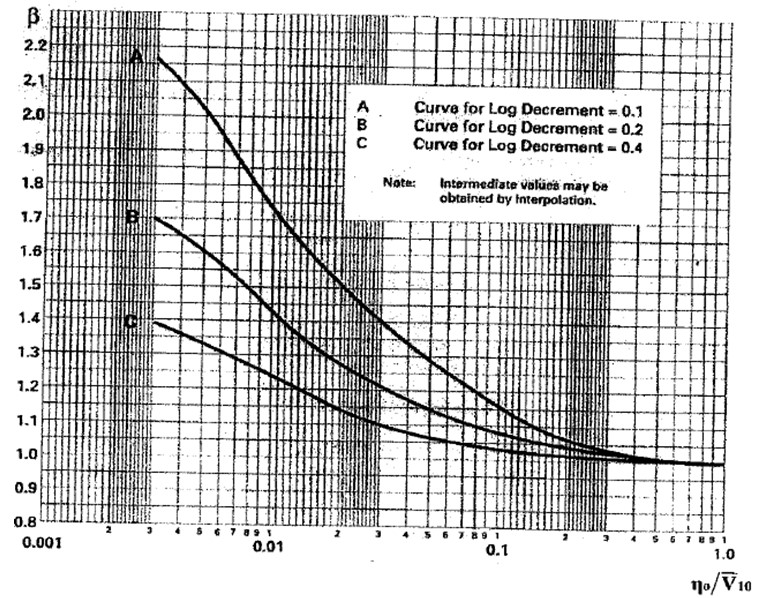

Diagrams illustrating wind forces and moments on high-mast lighting poles.

Determining Basic Wind Speed

Use ASCE 7-22 hazard tool for Risk Category II (typical). Exposure C for open terrain.